kairda-ndt

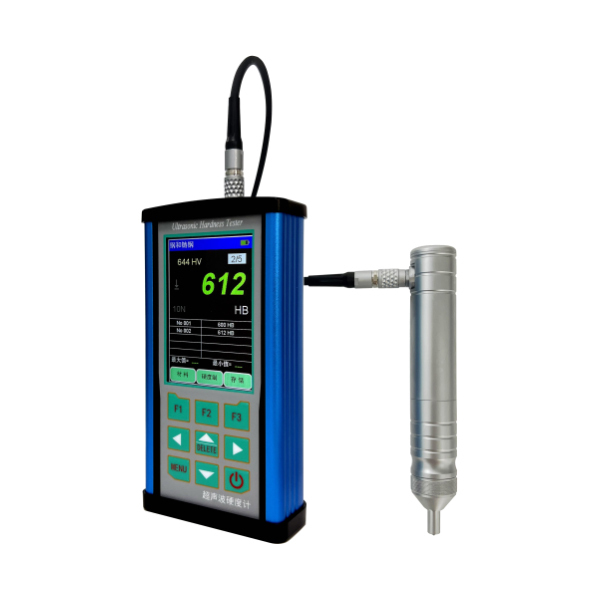

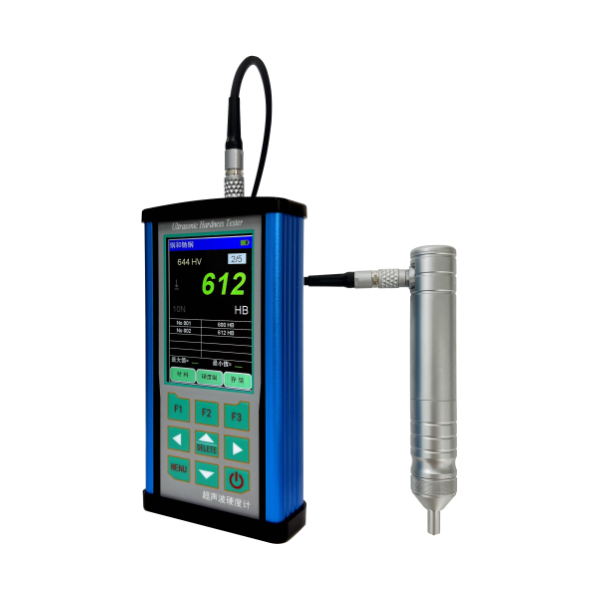

Ultrasonic Hardness Tester KH271

This ultrasonic hardness tester KH271 is an innovative design based on research on the principle of ultrasonic hardness measurement, it is using ultrasonic contact impedance method to compare and test patterns, the tester offers the calibration of probe, presents advantages of high precision, fast speed, easy operation, etc.

Ultrasonic Hardness Tester KH271, the hardness measurement covering most ferrous metals, non-ferrous metals and their alloys in industrial production. 3 User materials with setup guide was included.

The Ultrasonic Hardness Tester KH271 is applicable in measuring for hardness of flange edges, root of gear groove of stamping parts, thin plates, for surface-hardened gear grooves and its taper parts, as well as shafts, thin-walled pipes, turbines, hardened carburized layer of machining parts etc.

Features

- This Ultrasonic Hardness Tester KH271 accord to the Testing Standard GB/T 34205-2017

- This Ultrasonic Hardness Tester provides multi-point calibration function for any hardness standard based on your standard hardness samples, for materials with different elastic modulus

- This hardness Tester support hot-swap and self-calibration: automatically + by manual identifies the probe

- The material function includes 3 new material settings to facilitate hardness testing of special materials

- The display adopts IPS (In-Plane Switching) full digital LCD display no viewing angle, and the back light can be adjusted arbitrarily

- USB communication interface allows for data exchange and parameter setting with PC

- The upper and lower limits of the hardness value can be pre-set for the ultrasonic hardness tester, and an automatic alarm will be issued if the range is exceeded, which is convenient for users to meet the needs of batch testing

- 600 sets of hardness measurement data each includes measurement date, sensor type, material, number of times, single measurement value, average value, maximum value, minimum value, hardness scale and other information

- Optional are probe holder. 5kgf, 10kgf probe.

Technical Data of ultrasonic hardness tester

| Hardness scale | Vickers (HV), Brinell (HB), Rockwell (HRB), Rockwell (HRC), Rockwell (HRA) |

| Display Measurement | Vickers (HV) + selected hardness scale |

| Measuring materials | steel and cast steel, cast aluminum alloy, pure copper. |

| Display | 3.5-inch IPS full digital color LCD display, resolution 480×320. |

| Probe recognition | automatic recognition + manual setting, supports hot swapping |

| Data storage | maximum 600 measurement |

| Working voltage | 3.7V lithium-ion battery pack, |

| Charging power supply | 5V/1000mA, about 10 hours continuous working time |

| Communication interface | USB2.0 |

| Probe test force | 2kgf(optional , 5kgf, 10kgf) |

Probe specification

| Probe | 1kgf manual probe | 2kgf manual probe | 5kgf manual probe |

| Accessory Type | Optional accessory | Standard accessory | Optional accessory |

| Test force | 10N | 20N | 50N |

| Diameter | 22mm | 22mm | 22mm |

| Length | 150mm | 150mm | 150mm |

| Resonant rod diameter | 2.4mm | 2.4mm | 2.4mm |

| Maximum roughness of test surface | Ra<3.2um | Ra<5um | Ra<10um |

| Minimum workpiece weight | 0.3kg | 0.3kg | 0.3kg |

| Minimum workpiece thickness | 2mm | 0.3kg | 0.3kg |

xxxxxx

Your cart is currently empty.